NBR tires

These rubbers have balanced physical properties and their resistance to hydrocarbon solvents, oil and wear is very good and good against tearing, they also have a little resistance to ozone and moderate heat. Although they cannot be used against polar solvents, the gas can hardly penetrate these rubbers. In order to improve physical properties, nitrile rubbers are sometimes carboxylated, which will improve their temperature resistance.

Application of the product

This material is used in the automotive industry (production of gaskets, o-rings, hoses), shoe soles, conveyor belts, alloying with PVC, oil and gas tank liners, insulating foams, and in aviation for the production of fuel and oil control hoses.

NBR rubbers are divided into three groups according to the amount of nitrile in their construction: the amount of nitrile used plays a decisive role in the properties of this elastomeric material. (The higher the amount of nitrile, the more resistant NBR is)

- Low nitrile, using less than 30% nitrile.

- Medium nitrile, using 30 to 45% nitrile.

- High nitrile, using more than 45% nitrile.

Acrylonitrile is a toxic substance, but one of the interesting things about nitrile rubber is that it does not produce toxic substances when ionized.

The resistance of NBR rubber against perforation, cutting, tearing, corrosion and effectiveness against chemicals is three times that of natural rubber.

Nitrile rubber is an elastomeric material. This material is made by free radical emulsion polymerization of butadiene with 15-45% of acrylonitrile monomers.

The amount of nitrile used has a decisive role in the properties of this elastomeric material. (The higher the amount of nitrile, the more resistant NBR is)

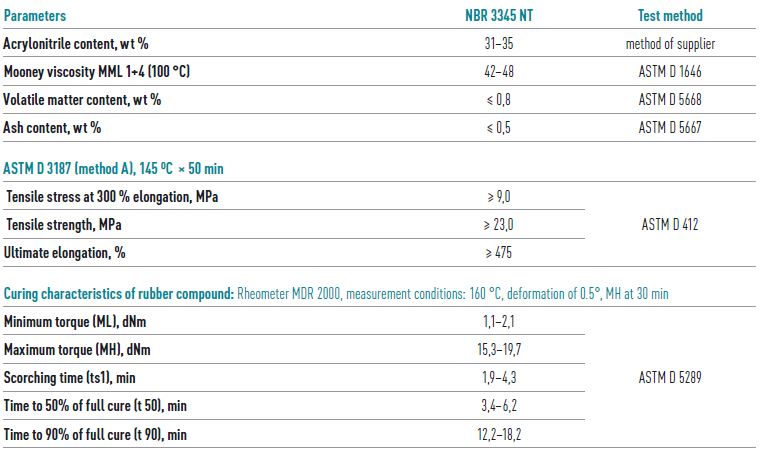

characterestic

characterestic table of this product